ORIGINAL RESEARCH | https://doi.org/10.5005/jp-journals-10024-2735 |

Comparative Evaluation of the Translucency of Monolithic Zirconia

1–4Department of Prosthodontics, Faculty of Dentistry, King Abdulaziz University, Jeddah, Kingdom of Saudi Arabia

Corresponding Author: Shatha A Alshali, Department of Prosthodontics, Faculty of Dentistry, King Abdulaziz University, Jeddah, Kingdom of Saudi Arabia, Phone: +966 564811876, e-mail: alshali.shatha@gmail.com

How to cite this article Alshali SA, Kazim SA, Nageeb R, et al. Comparative Evaluation of the Translucency of Monolithic Zirconia. J Contemp Dent Pract 2020;21(1):51–55.

Source of support: Nil

Conflict of interest: None

ABSTRACT

Aims and objectives: New techniques are being developed to invent zirconia with high translucency and better esthetics leading to the development of several brands of monolithic zirconia. The aim of this study is to compare the translucency of three brands of zirconia available for the fabrication of monolithic restorations.

Materials and methods: An in vitro study was designed to compare the translucency of three brands of zirconia available for the fabrication of monolithic restorations: Zirlux Zirconia (Vivadent Ivoclar), Zenostar Zr Translucent Zirconia (Weiland), and BruxZir Zirconia (Glidewell). All specimens were prepared to 0.5 mm thickness. Thirty zirconia specimens from each material were finished and polished. After drying, specimens were fired according to the manufacturers’ recommendations. A spectrophotometer (Color i5) was used for the translucency test. Each specimen was presented at the view port permitting the light to hit the center of the specimen. Results were saved into the software until all measurements were completed. The data were then transferred to an Excel sheet where translucency parameters were calculated. The one-way analysis of variance (ANOVA) test and the post hoc Bonferroni test were performed to analyze the results.

Results: The one-way ANOVA test revealed that there was a statistically significant difference between the groups. This study showed lower translucency of BruxZir in comparison to Zenostar and Zirlux when tested under standardized conditions.

Conclusion: There is a statistically significant difference in the translucency between the different brands of zirconia available for monolithic restoration fabrication.

Clinical significance: Different brands of zirconia have different degrees of translucency. Material selection should be customized in each case.

Keywords: Monolithic, Translucency, Zirconia.

INTRODUCTION

The shift in dentistry to restorations that mimic natural teeth is undeniable. The search for strong, long-lasting esthetic restorations that match the long-standing functional predictability of gold restorations has started since the beginning of the dental practice. Based on actual patient demand regarding esthetic and health concerns, material choices have shifted to metal-free restorations due to their esthetic properties and biocompatibility.1–3

Originally, zirconia crowns were made with a zirconia substructure layered or pressed with different types of porcelain. Esthetic, strong, biocompatible, durable, conservative, and price-competitive are few of the qualities that promote many laboratories turning to full-contour monolithic restorations.4–8 In addition, digital technology enabled laboratory and dentists to shape and manipulate such completely dense zirconia to contoured crowns in shorter time. Interestingly, it offers patients the convenience of same-day dentistry.5,6,8–11

Monolithic zirconia restorations begin as chalky white blocks with low translucency that are milled to their designed shape and soaked in a dyeing liquid.5 The push to achieve millable monolithic materials has encouraged the invention of higher translucent zirconia millable materials in shaded gradations and different opacities to improve the esthetics of the product. After adjusting some compositional items and powder physical characteristics, zirconia achieved higher translucency. The zirconia-producing company’s goal is to be able to develop zirconia powders that match all the shades in the VITA shade guide and to produce high-density milling blocks that are more translucent and without loss in strength.12 Nowadays, new techniques are being developed and used to achieve zirconia with high translucency and better esthetics leading to the development of several brands of monolithic zirconia.13 Thus, it is important to perform comparative evaluation of the translucency of the available new brands of monolithic zirconia materials with enhanced esthetics.

MATERIALS AND METHODS

An in vitro study was designed to compare the translucency of three different brands of zirconia available for the fabrication of monolithic restorations: Zirlux Zirconia (Vivadent Ivoclar), Zenostar Zr Translucent Zirconia (Weiland), and BruxZir Zirconia (Glidewell).

Preparing the Ceramic Specimens

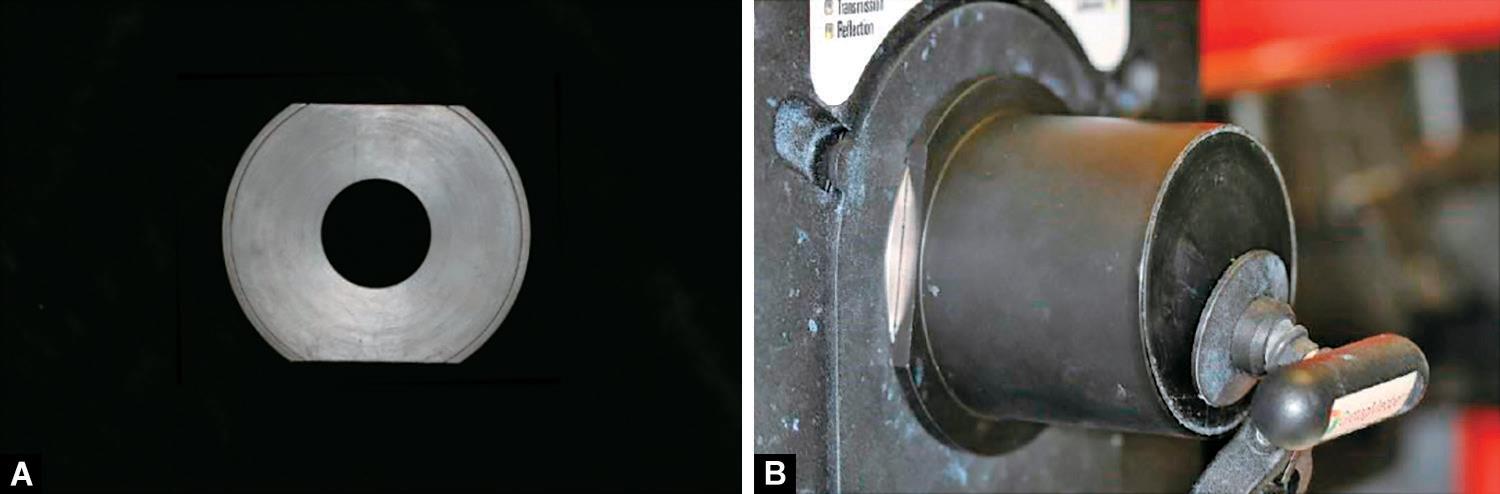

All specimens for translucency testing were prepared to 0.5 mm thickness (Fig. 1). The presintered discs were firmly held by a special metal holder in position where it can be cut into dimensions using an ISOMET 2000 Precision Saw. After cutting, the grinder and polisher system (Buehler, EcoMet 250 Grinder-Polisher, Buehler Ltd., IL, USA) was used to finish and polish the 30 zirconia specimens from each material on both sides, starting with diamond grits 45 and 15 μm with water, respectively. Then with 6 and 1 μm polycrystalline diamond suspensions in series applied to special wheels. After drying, the 90 specimens were fired following the manufacturer’s instruction in a Zercomat furnace (VITA Zyrcomat T, VITA Zahnfabrik H. Rauter GmbH and Co.KG). The specimens experienced shrinkage of about 20% after firing to create 0.5-mm-thick specimens.

Fig. 1: Ceramic specimen measuring 0.5 mm thick for translucency testing

Performing the Translucency Test

A Color i5 (GretagMacbeth, Regansdorf, Switzerland, serial no. 150269) spectrophotometer, version 7.0.28, was used for collecting data (Fig. 2). The repeatability and inter-instrument agreement of the spectrophotometer was tested using the X-rite calibrated BCRA series II ceramic standards STD29. Measurements were completed using CIE LAB, illuminant D65 10° observer at a corrected standard temperature.

Testing usually started with calibrating the device. The software will ask to place the standard white circle tile on the specimen arm to be held against the aperture port plate opening. An average of two readings per specimen are taken. Then, the software will ask to place the standard black trap and take another average of two readings on the black background. Calibration is recommended every 8 hours of operation.

After calibration is completed, the specimen was presented at the view port to allow the light to hit the center of the specimen. The specimen is held in place by taping the edges of the specimen (Fig. 3). The specimen was labeled on the data box window that appears in the software. The standard white circle tile was held against the specimen by the specimen arm and an average of two readings were taken (Fig. 4). Then, the standard white tile was removed, and the standard black trap was positioned on the specimen arm and held against the specimen (Fig. 5). Again, an average of two readings were taken. All the data were saved into the software until measurements were completed.

Fig. 2: Color i5 Benchtop spectrophotometer

Fig. 3: Specimen is held against the view port

The data were then transferred to an Excel sheet where translucency parameters were calculated in accordance with the following equation:

where the subscript w refers to color coordinates CIELAB with the white backing and the subscript b refers to those against the black backing.

RESULTS

Translucency testing results are shown in Table 1. The mean translucency parameter (TP) value of the different materials tested is illustrated in Figure 6. The mean difference was significant at or below 0.05 (p = 0.05). A one-way analysis of variance (ANOVA) test revealed that there was a statistically significant difference among the groups (Table 2). To clarify the differences among the groups, a post hoc Bonferroni test for multiple analyses was also performed (Table 3). The SPSS software was used for statistical analysis. The results showed a lower translucency of BruxZir in comparison to Zenostar and Zirlux when tested under standardized conditions. There is no excessive change in the translucency but is statistically significant.

DISCUSSION

Among a diversity of ceramic materials, zirconia has been regarded as “Ceramic Steel.” Its opacity has always been a limiting factor. It consistently established the least translucency whenever the relative translucency of zirconia was compared to other available esthetic restorative materials. Although Heffernan et al.14 showed that zirconia-based restorations provided higher translucency and better esthetics than porcelain fused to metal restorations. They and Chen et al.15 reported that zirconia had the least translucency compared to all other all-ceramic restorations. Furthermore, they elaborated on the masking properties of these opaque materials.

Figs 4A and B: Measuring the luminous reflectance of the specimen with white backing

Figs 5A and B: Using black backing to measure the luminous reflectance of the specimen

| Translucency test | |||

|---|---|---|---|

| BruxZir | Zirlux | Zenostar | |

| Specimen size | 30 | 30 | 30 |

| Mean | 11.92232956 | 12.74174578 | 12.94178496 |

| SD | 0.762475591 | 0.77158542 | 1.035420662 |

| CoV (%) | 6.395357444 | 6.055570668 | 8.000601657 |

Fig. 6: Mean translucency parameters of different zirconia

Even though, zirconia is considered to be the lower hand in translucency, previous studies were able to establish a significant difference in the relative translucency of the different zirconia-based core materials. These results are in accordance with a study done by Baldissara et al.,16 which determined the most translucent zirconia coping that can be used to improve esthetics and the least translucent zirconia coping that can be used for masking purposes. In our study, we were also able to demonstrate a significant difference between the different brands of zirconia available for monolithic restoration fabrication.

The materials tested in this study are mainly polycrystalline ceramic with no glass content. According to Heffernan, the amount of absorbed, reflected, and transmitted light will differ with the crystals content in the matrix, the chemical nature of the crystals, and the particles size in comparison to the wavelength of the incident light.14 The results of the present study are in accordance with Heffernan’s results; since BruxZir zirconia was determined to be less translucent than Zirlux and Zenostar, BruxZir demonstrated a larger grain size.

Several factors can affect the translucency related to the specimen, the material itself, or the measurement process such as specimen thickness, crystal structure, surface texture, material’s batch, etc. Effort was made to limit the variables that could change the TP measurement, which is considered as strength in this study. Also the small average deviations found in the groups confirmed consistency in specimen’s production and control over variables.

The literature has revealed that thickness inversely affects the light transmission through dental ceramics.14,17,18 For this reason, in this study, the measurement of the specimen’s thickness was taken three times and the means were compared between groups. No statistical difference was found between groups and the low variability within groups was confirmed by the low standard deviations, which insured the consistent specimen thickness. The controlled specimen thickness confirmed that the variances in translucencies among groups were not due to different specimen thicknesses.

| One-way ANOVA tab | |||||

|---|---|---|---|---|---|

| Source | Sum of squares | Degree of freedom | Mean square | F | p value |

| Between variation | 17.507 | 2 | 8.754 | 11.678 | 0.0000 |

| Within variation | 65.215 | 87 | 0.750 | ||

| Total variation | 82.723 | 89 | |||

| Bonferroni method | ||||

|---|---|---|---|---|

| Difference | Mean difference | Lower | Upper | Significance |

| BruxZir−Zirlux | −0.819 | −1.365 | −0.274 | Yes |

| BruxZir−Zenostar | −1.019 | −1.565 | −0.474 | Yes |

| Zirlux−Zenostar | −0.200 | −0.746 | 0.346 | No |

Out of concern for clinical significance, the specimen thickness of 0.5 mm was chosen, as it is the minimum thickness that the manufacturers suggested during the fabrication of monolithic zirconia crowns and bridges. While manufacturers claimed that it is viable to create thinner restorations up to 0.3 mm thickness without compromising the strength of the material, the thickness of 0.5 mm was selected for all materials being the favored minimum thickness to establish better occlusal anatomy and harmonious blend.

Surface texture can also affect the translucency of ceramics. Uhlmann et al. stated that a very smooth glossy surface would reflect light at the same angle as incidence, developing in specular reflection.19 This variable perhaps had no affect on the results of this study since the comparisons were done between comparative values of translucency and also due to the standard polishing procedure that was followed leading to a consistent appearance for all specimens’ surfaces. Also, we decided in our study not to glaze the specimens because that could interfere with the results of translucency. Furthermore, it would not have been easy to control the amount of the glazing material in each surface, which could have led to inconsistency within groups.

Recently, many techniques have introduced translucency to zirconia. Some researchers combine nanopowders to full density with nanocrystals through the industrial sintering technique and these zirconia products have been broadly used.20 Others introduce fine grain size with less alumina, utilizing the isotropic cubic zirconia to cut down on light scattering, thus improved translucency.13,21 New brands of monolithic zirconia have been developed with minimal, even eliminated alumina content or others with increased yttria content to improve the translucency of monolithic yttria-stabilized tetragonal zirconia polycrystal restoration.13,22 Recent study claims that multilayer monolithic zirconia has improved optical and mechanical properties than the conventional monolithic zirconia.23 The manufacturers of zirconia dental ceramic could adopt those methods to highlight the great mechanical and physical properties of zirconia with optimal translucency for wider clinical application and esthetic satisfaction.

CONCLUSION

Regarding the newly developed materials for monolithic restorations, there are no studies that rank the relative translucencies. This study showed a lower translucency of BruxZir in comparison to Zenostar and Zirlux when tested under standardized conditions. There is no excessive change in the translucency but is statistically significant. It was possible that reducing crystal sizes of Zenostar and Zirlux contributed to their higher degree of translucency.

ACKNOWLEDGMENTS

The author is very thankful to all the associated personnel in any reference who contributed in/for the purpose of this research. Further, this research holds no conflict of interest and is not funded through any source.

REFERENCES

1. Griffin JJJr. Combining monolithic zirconia crowns, digital impressioning, and regenerative cement for a predictable restorative alternative to PFM. Compend Contin Educ Dent 2013;34(3):212–222.

2. Spear FM. The metal-free practice: myth? Reality? Desirable goal? J Esthet Restor Dent 2001;13(1):59–67. DOI: 10.1111/j.1708-8240.2001.tb00252.x.

3. McLaren E, Giordano R. Ceramics overview: classification by microstructure and processing methods. Compend Contin Educ Dent 2010;31(9):682–684.

4. Piconi C, Maccauro G. Zirconia as a ceramic biomaterial. Biomaterials 1999;20(1):1–25. DOI: 10.1016/S0142-9612(98)00010-6.

5. Long HA. Monolithic zirconia crowns and bridges. Inside Dent 2012;8(1):60–66.

6. Wall JG, Cipra DL. Alternative crown systems. Is the metal-ceramic crown always the restoration of choice? Dent Clin North Am 1992;36(3):765–782.

7. Griffin JDJr. Tooth in a bag: same-day monolithic zirconia crown. Dent Today 2013;32(1):124,126-131.

8. Moving to monolithic. Inside Dental Technology: AEGIS; 2011.

9. McLaren E. CAD/CAM dental technology. Compend Contin Educ Dent 2011;32(4):73–76.

10. Strub JR, Rekow ED, Witkowski S. Computer-aided design and fabrication of dental restorations: current systems and future possibilities. J Am Dent Assoc 2006;137(9):1289–1296. DOI: 10.14219/jada.archive.2006.0389.

11. Mitov G, Heintze SD, Walz S, et al. Wear behavior of dental Y-TZP ceramic against natural enamel after different finishing procedures. Dental Mater 2012;28(8):909–918. DOI: 10.1016/j.dental.2012.04.010.

12. Johnson P. Next generation materials: material developers shape the future direction of the industry. Inside Dental Technology. Compend Contin Educ Dent 2012;3:3.

13. Sulaiman TA, Abdulmajeed AA, Donovan TE, et al. Optical properties and light irradiance of monolithic zirconia at variable thicknesses. Dent Mater 2015;31(10):1180–1187. DOI: 10.1016/j.dental.2015.06.016.

14. Heffernan MJ, Aquilino SA, Diaz-Arnold AM, et al. Relative translucency of six all-ceramic systems. Part I: core materials. J Prosthet Dent 2002;88(1):4–9.

15. Chen YM, Smales RJ, Yip KH, et al. Translucency and biaxial flexural strength of four ceramic core materials. Dent Mater 2008;24(11):1506–1511. DOI: 10.1016/j.dental.2008.03.010.

16. Baldissara P, Llukacej A, Ciocca L, et al. Translucency of zirconia copings made with different CAD/CAM systems. J Prosthet Dent 2010;104(1):6–12. DOI: 10.1016/S0022-3913(10)60086-8.

17. O’Keefe KL, Pease PL, Herrin HK. Variables affecting the spectral transmittance of light through porcelain veneer samples. J Prosthet Dent 1991;66(4):434–438. DOI: 10.1016/0022-3913(91)90501-m.

18. Terzioğlu H, Yilmaz B, Yurdukoru B. The effect of different shades of specific luting agents and IPS empress ceramic thickness on overall color. Int J Periodontics Restorative Dent 2009;29(5):499–505.

19. Uhlmann DR, Bowen HK, Kingery WD. Introduction to ceramics. 1976.

20. Jiang L, Liao Y, Wan Q, et al. Effects of sintering temperature and particle size on the translucency of zirconium dioxide dental ceramic. J Mater Sci Mater Med 2011;22(11):2429–2435. DOI: 10.1007/s10856-011-4438-9.

21. Sulaiman TA, Abdulmajeed AA, Donovan TE, et al. The effect of staining and vacuum sintering on optical and mechanical properties of partially and fully stabilized monolithic zirconia. Dent Mater J 2015;34(5):605–610. DOI: 10.4012/dmj.2015-054.

22. Yu B, Ahn JS, Lee YK. Measurement of translucency of tooth enamel and dentin. Acta Odontol Scand 2009;67(1):57–64. DOI: 10.1080/00016350802577818.

23. Elsaka SE. Optical and mechanical properties of newly developed monolithic multilayer zirconia. J Prosthodont 2019;28(1):e279–e284. DOI: 10.1111/jopr.12730.

________________________

© The Author(s). 2020 Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by-nc/4.0/), which permits unrestricted use, distribution, and non-commercial reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.